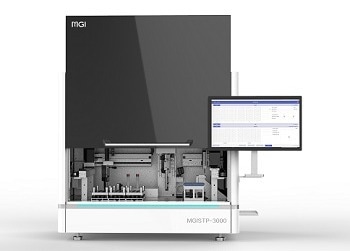

MGISTP-3000 from MGI is considered a benchtop automated sample transfer processing system. It combines tube decapping, barcode identification, tube recapping, automated liquid transfer, and negative pressure protection.

MGISTP-3000 provides high torque decapping gripper, 23-in touch screen, and HEPA filters, ensuring the utmost filtration efficiency of 99.995% at 0.3 µm. Moreover, MGISTP-3000 enables users to load three types of tubes in the same run.

Users can transfer 96 samples from screw cap transport tubes to 96-Well Microplates in nearly 40 minutes. A HEPA filter purifies inflow and exhaust air to avoid aerosol pollution and ensure a secure working environment for nucleic acid extraction and laboratory technicians.

Features

Automated: Completely automated—offers tube decapping, tube recapping, barcode identification, and automated liquid transfer functions.

Easy to use: Comes with a user-friendly GUI touch screen and enables users to load three types of tubes in a similar run.

Safe: Two HEPA-filtration and one UV light guarantee a more secure working environment for both liquid transfer and laboratory technicians.

High Reliability: Users can automatically log common errors without requiring human intervention to guarantee continuous functioning.

Image Credit: MGI

Performance parameter

Table 1. Source: MGI

| MGISTP-3000 |

| Throughput |

96 Samples/40 min |

| Pipetting Method |

Based on the principle of air displacement |

| Volume Range |

10 μL:<±10% ; 100 μL:<±5%; 1000 μL:<±2% |

| Accuracy |

10 μL:<±10% ; 100 μL:<±5%; 1000 μL:<±2% |

| CV |

10 μL:<5% ; 100 μL:<2%; 1000 μL:<1% |

| Robot Arm Accuracy |

X-Y-Z:±0.1 mm |

| Barcode Scanner |

1D and 2D |

| UV Light |

3*8 W |

| Supply/Exhaust Air Filter |

Exhaust / Inflow HEPA filtration efficiency of 99.995% at 0.3um, Negative Pressure System |

| Tube Compatibility |

5-15 mL transport tube with screw cap. |

| Functions |

Integrate multiple functions, including decapping, recapping, barcode identification, automated liquid transfer, HEPA-filtration and negative pressure protection. |

System parameter

Table 2. Source: MGI

| . |

. |

| Power & Dimensions & Net Weight |

Dimensions: Length 1100 mm, Width 680 mm, Height 1050 mm

Net Weight: <200 kg

Power Type: 100 ~ 240 V,50/60 Hz

Rated Power: 600 VA |

| Operating Environment Requirements |

Temperature: 19-25 ℃

Relative Humidity: 20% RH ~ 80% RH, non-condensing

Atmospheric Pressure: 80 ~ 106 kPa |